WE ARE THE QUALITY WE WANT TO ACHIEVE

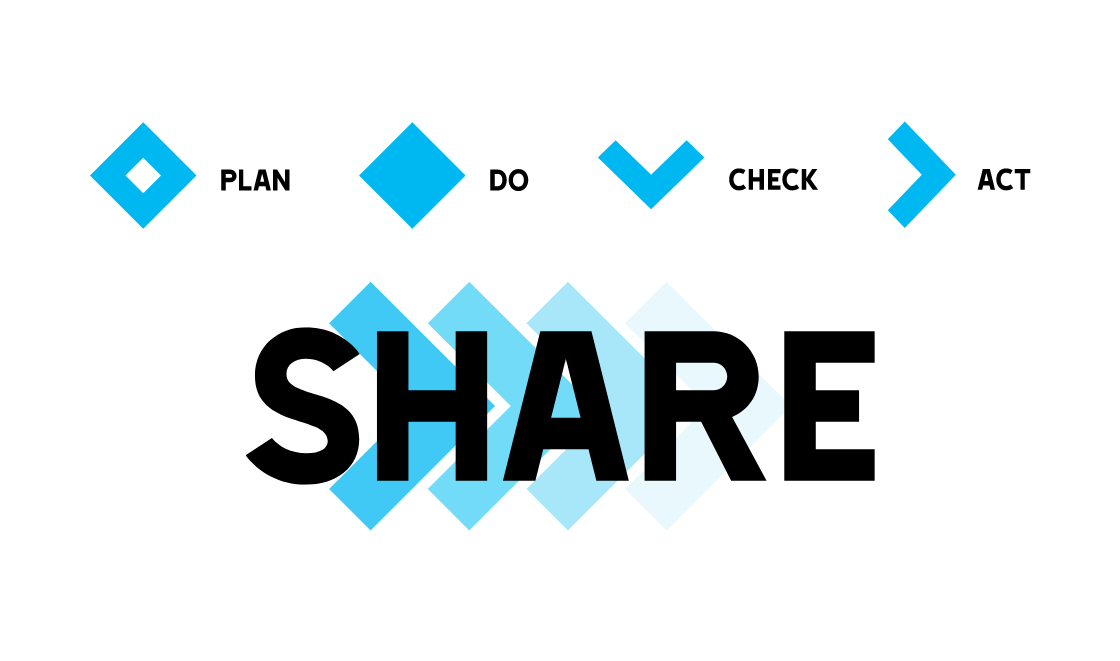

CAME's working methodology is based on the continuous improvement of production processes,

security and relationships, but a great result can only be achieved with the contribution of all.

Q.I. comes from this awareness. - Quality Inside - a project involving

CAME’s women and men and the professionals who rely on our products to offer increasingly reliable and innovative solutions that improve the quality of life of their customers.